High-Quality Investment Castings

Investment castings are what we do.

Based in Muskegon, Michigan, Eagle Precision Cast Parts, Inc. produces ferrous and non-ferrous investment castings. Our castings are manufactured to +/-.005 per inch through a process that has the capabilities of producing extremely thin sections, knife edges, and sharp detail. Eagle Precision produces a wide range of sizes and configurations of investment castings ranging from a fraction of an ounce up to 90 pounds net weight, including both small and large volume orders.

Advantages of Investment Casting

Investment casting is one of the most accurate and precise metalcasting techniques available. Using our time-tested process we can manufacture castings with tighter tolerances, thinner sections and more vivid details than other types of foundries. We’re also able to cast products using nearly any alloy, from stainless steel to bronze. Investment casting tooling also lasts longer than tooling for other casting methods, which is potentially a cost saver for large runs.

Investment casting is one of the most accurate and precise metalcasting techniques available. Using our time-tested process we can manufacture castings with tighter tolerances, thinner sections and more vivid details than other types of foundries. We’re also able to cast products using nearly any alloy, from stainless steel to bronze. Investment casting tooling also lasts longer than tooling for other casting methods, which is potentially a cost saver for large runs.

If you’ve never worked with an investment casting facility before, you’ll be surprised by the amount of detail we can achieve in an as-cast part. Machining costs can be drastically reduced. Investment casting also lends itself well to conversions from fabricated or fully machined parts. Parts that seem un-castable can be redesigned for investment casting, often resulting in better looking, better quality and less expensive parts.

To see a number of examples of our capabilities, take a look at our Industries page.

The Investment Casting Process

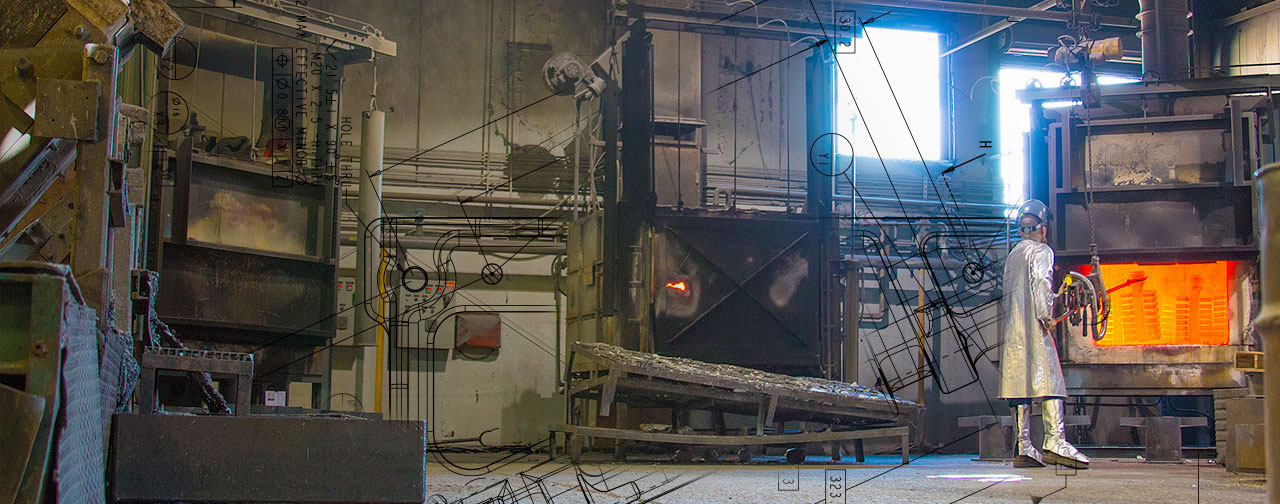

The investment casting process is unique among metalcasting methods, and differs from sand casting in a number of ways. The first step in investment casting is to create a wax-injection die, which will serve as the primary tooling throughout the casting process. The die is then used to produce a number of wax patterns, similar to die casting but using wax instead of molten metal. The wax patterns are then affixed to a sprue to form what’s called a “tree,” or a cluster of wax patterns. This assembly is then dipped in a number of slurries, coated with sand and left to dry.

Once dry, the molds are placed in a furnace and raised to a temperature sufficient to liquify the wax at the center of the molds. The wax then flows out of the molds to be collected and reused, leaving only empty ceramic molds. The molds can then be pre-heated and poured. Molten metal is poured into the ingate and flows through the sprue and into each mold cavity.

After the molds have sufficiently cooled, the ceramic shell can be broken away to reveal the metal parts.

To learn more about the investment casting process, download our Investment Casting Process Guide.

Additional Investment Casting Services

Eagle Precision Cast Parts is a full-service manufacturing facility. We provide engineering support from the very beginning of each investment casting project in order to ensure that the process and the part itself are optimized for production. We utilize Advanced Product Quality Planning (APQP) in order to efficiently learn the product and application requirements of each part and translate that knowledge into a successful investment casting.

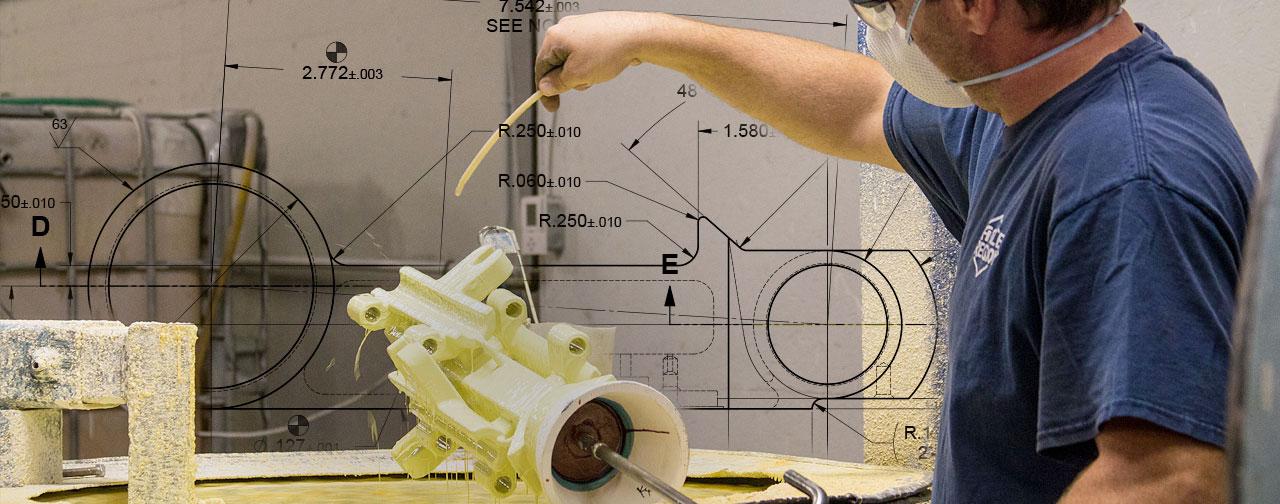

Our team also has extensive skills in 3D solidification software and advanced metrology. Not only can we provide accurate measurements in a fraction of the time it takes many casting facilities, but we can present measurement data in a wide variety of formats. Whether you prefer standard blueprints or an interactive tolerance chart, we have the in-house capabilities to visualize your measurement data.

Finally, we are able to offer turnkey assembly services to ensure that we provide each customer with a finished product ready for sale.

Learn more about what we do on our Services page.

About Eagle Precision Cast Parts

Eagle Precision was started in 1993, and is proud to be a part of the Eagle Group. We occupy a newly expanded 55,000 square foot manufacturing facility located on the same grounds as another foundry within our group. Lean manufacturing and continuous improvement have enabled us to increase capacity and improve throughput.

Our business philosophies are built on Service, Quality, Delivery, and Cost; and our ‘”customer first” attitude is evident in all that we do! To find out what Eagle Precision Cast Parts can do for you and your products, contact us today.